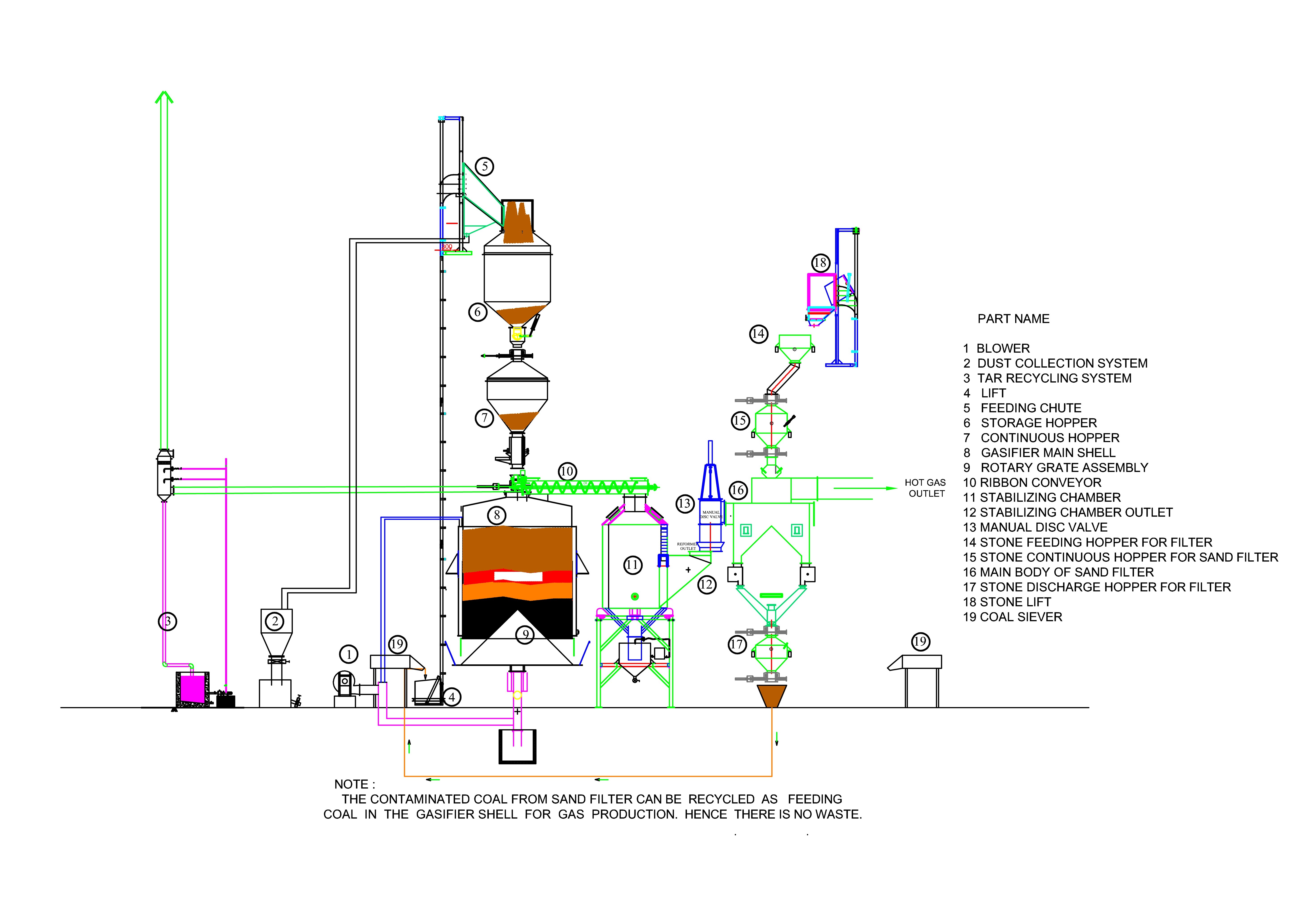

Up Draft Hot Filtration Technology

UP DRAFT HOT FILTRATION

- Aim to utilize direct clean and hot gas.

- Tar is remaining in gaseous form and utilize in furnace as fuel with producer gas (coal gas).

- Outlet temperature of gas up to 300-450’c

- Utilization of Hard Coal as filter media for cleaning of HOT gas which can be re-utilize in Gasifier Shell with fresh feed coal easily.

- Tar and phenolic water free producer gas will ease The process and no handling of waste water and tar.

- No gas scrubbing so no fresh water required hence no waste water generation.

- No waste water so no extra evaporation required, will reduce fuel cost.

- Less space, less equipment, less electricity high energy efficient technology

- Hot gas and tar in vapor form increase the gasifier efficiency ( it reduces 20-25% fuel consumption)Ultimately reduces the green house emission.

- No by product generation and no residue left out ( zero discharge)

- Completely environmental friendly technology

- Process control with fully automatic scada control system, totally user friendly process.

- Low capital investment

- Potential saving of huge natural resources.

Merits and comparison.

Merits and comparisons of HOT gas filtration system & cleaning gasification technology with updraft wet cleaning gasification technology.

| SR.NO. | FEATURES | UPDRAFT WET CLEANING TECHNOLOGY | NEWLY HOT GAS FILTRATION AND CLEANING SYSTEM GASIFICATION TECHNOLOGY |

|---|---|---|---|

| 1 | Additional energy require |  |

|

| 2 | Risk of explosion |  |

|

| 3 | Residue generation(Waste Water, Coal Tar) |  |

|

| 4 | Need to disposal of residue |  |

|

| 5 | Require complex additional equipment(waste water evaporator, cooling tower & tar disposal & ESP) |  |

|

| 6 | Skill manpower for operation |  |

|

| 7 | Energy efficiency | Low | Very high |

| 8 | Equipment, maintenance and operation cost | High | Very Low |

| 9 | Environment friendly, complete zero discharge | No but need precise attention for residue disposal | Almost zero discharge |

Application

- Ceramic Industry

- Glass Industry

- Chemical Industry

- Special Alloys

- Aluminium Industry

- Special Glass Industry

- Galvanized Wire Industry

- Steel Pellet Rotary Dryer

- Paper Industry

- Cement Industry

Hot Gas Filtration Gasification technology

Green Technologies